Advantages of PM VSD Screw Air Compressor(B&D brand)

1. FRONT MESH

Filter the air before come into compressor, which make good protection for air end and compressor is more durable.

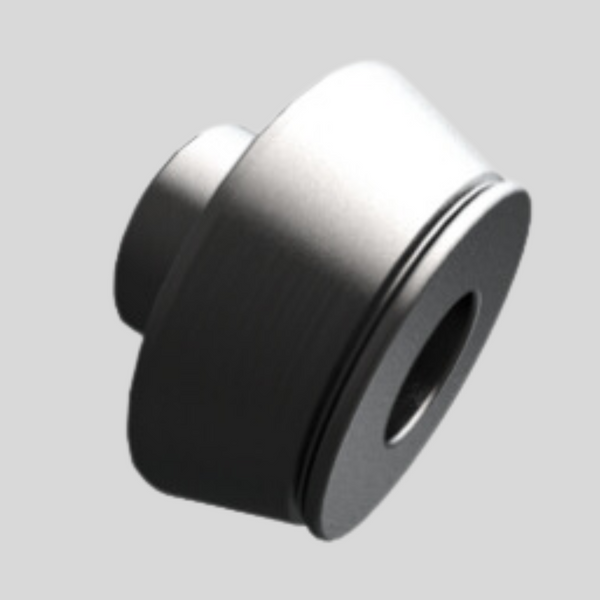

2. ONE-PIECE AIR END&MOTOR

Permanent magnet motor is a synchronous motor, uses Neodymium Boron material and never lose magnetism until 120℃. Stator coil is more durable as it’s wrapped by corona resistant enameled wire. PM motor is improved efficiency by 9%, surpassing asynchronous motor, and designed for 10 years reliable operation.

High efficiency Aluminum alloy Oil-cool motor

The applications of High efficiency Aluminum alloy Oil-cool motor in our air compressors are unique and first in this air compressor industry. With advantages of light-weight, fast-cooling, low noise(which can lower to 60-70dB(A)), our self-patented aluminum alloy oil-cooled motors dominate relevant product series(LS series, PM-TK series, EPM series) from average air compressors of competitors.

Air end connect with PM motor by one shaft without coupling or bearing. Transmission rate reach 100%. If works with inverter, energy efficiency is improved as much as 6%.

Air end production line introduces Germany & Japan high precision rotor grinding machinery. Optimized rotor profile delivers more flow than capacity of similar parts therefore help minimize the operating expense.

3. VARIABLE SPEED DRIVE

Variable speed drive control speed of motor and decrease start current, make operation smoothly and quietly. The VSD(inverter) can save up to 35% on energy costs. For whole compressor, VSD together with efficient PM motor, this rate even reach 42%.

4. INTELLIGENT CONTROLLER

PLC controller helps you properly maintain air compressor. React automatically to key parameters to reduce unexpected downtime. Monitor and adjust parameters on the touch screen panel and can send you message to your cell phone when operational events occur. So you can take immediate action, accessing compressor system from anywhere in the world only with a web-browser.

5. COOLING SYSTEM

Enlarged heat exchanger reduces significant thermal for improved durability.

6. SMART COMPRESSOR

A program lets you start/stop compressor at specific time. Fix the pressure at your own demand to maximize productivity and save energy.

7. LONG LIFE COMSUMABLE

Oil separation system remove all 3ppm oil from compressed air, protecting equipment system and minimize costs.

8. PRESSURE CONTROL

You can fix the pressure at your own demand within a certain range, compressor delivers airflow the same as needed and minimize energy consumption.

TECHNICAL DATA

| MODEL |

DHF-10PM |

DHF-15PM |

DHF-20PM |

DHF-30PM |

| Power(kw) |

7.5 |

11 |

15 |

22 |

| FAD(m³/min) |

Pressure(bar) |

0.36-1.35 |

0.46-1.8 |

0.8-2.6 |

1.0-3.8 |

| 8 |

| Ambient temp |

-5~+45℃ |

| Cooling Way |

Air Cooling |

| Discharge temp |

air cooling(ambient temperature±10℃) water cooling(<40℃) |

| Electricity |

380v/50hz |

| Starting Method |

Inverter Start |

| Drive way |

PM Variable Speed Synchronization |

| Lubricant(Litre) |

4 |

9 |

9 |

16 |

| Noise(dBA) |

62±2 |

65±2 |

65±2 |

65±2 |

| Length(mm) |

800 |

940 |

940 |

1120 |

| Width(mm) |

550 |

630 |

630 |

765 |

| Height(mm) |

730 |

830 |

830 |

930 |

| Weight(kg) |

160 |

260 |

365 |

410 |

| Outlet Pipe Dia(inch) |

ZG½" |

ZG1" |

ZG1¼" |

ZG1¼" |

Delivery

We offer a $50 delivery service to Auckland and surrounding areas (within 150km).

Freight can be arranged at buyer's co

Shipping & pick-up options

| Destination & description |

Price |

| Nationwide Mainfreight Depot |

$350.00 |

| Pick-up available from Auckland City, Auckland |

Free |